Oversea:+86-13790081902

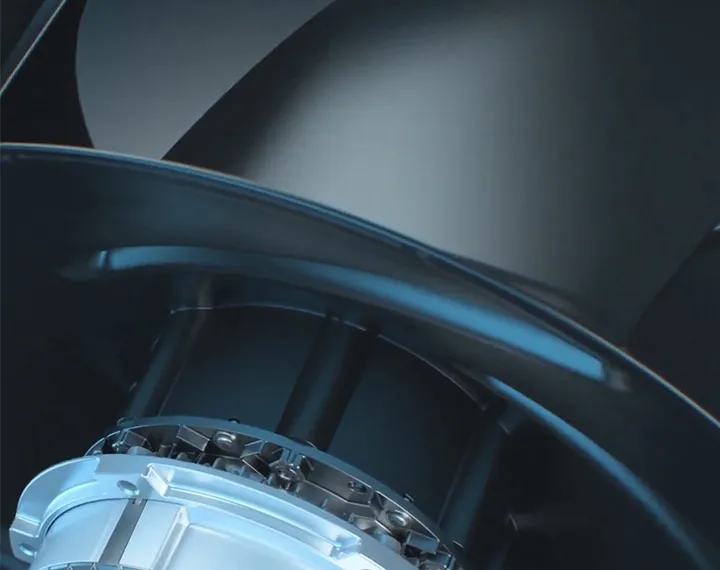

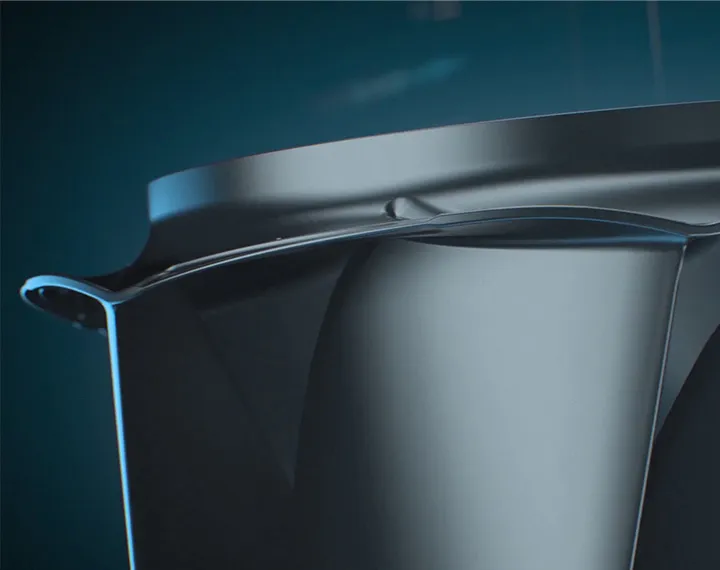

Backward curved centrifugal fans feature blades that curve away from the direction of the impeller's rotation, resulting in larger and more curved blades compared to other types. This design enables improved airflow control, minimizes turbulence, and reduces dust and debris accumulation, making backward curved centrifugal fans suitable for clean air environments. These fans typically generate medium to high airflow volumes at low to medium pressures, with efficiencies ranging from 80-90%, positioning backward curved centrifugal fans as the most energy-efficient among centrifugal fan types. Key performance traits include a non-overloading horsepower characteristic, meaning there is no stall point, allowing reliable operation across the entire performance curve without excessive power draw. Backward curved centrifugal fans often have large inlet and outlet openings, wide casings, and can produce more noise due to their blade size, though modern designs are quieter. Variations include airfoil wheels (hollow, wing-shaped blades for clean, dry airstreams), single-thickness wheels (flat blades for moderate material and moisture), and backward curved wheels (solid, curved blades with similar handling capabilities).

中文

中文  English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Polska

Polska