Oversea:+86-13790081902

EC stands for Electronically Commutated, which combines AC and DC voltages to achieve a perfect phase change between the two voltages.

The motor runs on DC voltage and can be powered by either a single-phase 230VAC or three-phase 380VAC supply. The motor contains the voltage conversion control circuit inside the motor.

The non-rotating part of the motor (stator) is extended to make room for the electrical circuit board, which includes the AC to DC power conversion as well as the controller.

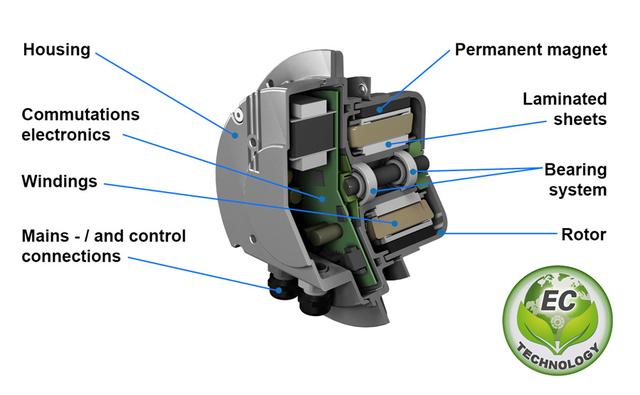

Our EC motor (electronically commutated) is a Hall-less three-phase permanent magnet synchronous external rotor type motor (PMSM for short). In the commutation circuit, the AC voltage is converted to DC voltage by the commutator.

The motor position depends on the voltage provided through the inverter module (similar to the principle of frequency converters).

EC circuit boards differ from frequency converters in that they decide how to provide current (commutation) to the motor phases in the stator based on position, direction of rotation and default values.

EC external rotor motor structure diagram

The permanent magnets in the rotor generate the magnetic field required for full load operation. This allows high efficiency, low noise and continuous motor speed control. The mounting flange on the rotor is used for impeller assembly. Depending on the motor type, the terminal box is equipped with a cable screw connection or a connecting cable to facilitate quick connection. Depending on the application area, additional control functions (such as constant pressure control, volume flow control, temperature control) can be adopted.

Conventional DC motors have a housing that contains all components such as carbon brushes, commutator, bearings, armature with windings, etc. They are arranged one after another. With EC motor components, more space is saved, and collectors and carbon brushes are not required. As a result, the motor is significantly shorter and therefore has advantages in terms of size and quiet operation during installation.

Compared with conventional motors, the investment cost of the EC exhaust fan is slightly higher, but due to low energy consumption and low installation costs (no transformer control, frequency converter or phase angle control is required), they can mostly be amortized in the shortest operating time.

Under the current environmental requirements of carbon peak, our domestic motor and fan manufacturers are constantly rising and making real contributions to the beautiful future of green waters and green mountains around the world!

At SunxFan, we pioneer smart airflow technology by integrating motor design, electronic control, and fluid dynamics into our EC fan systems. Since our founding in 2017, we’ve focused on deep technological innovation that redefines energy efficiency and performance in industrial and commercial ventilation applications, enabling precise speed regulation, reduced operating costs, and sustainable airflow solutions for HVAC, data center cooling, and complex ventilation systems.

Our EC fans — including EC forward-curved centrifugal blower, EC axial fans, EC duct fans, and so on — are engineered for 24/7 operation with intelligent control features that adapt to real-time demand, delivering superior efficiency, lower noise, and long service life. Besides, as one of the professional backward curved centrifugal fan manufacturers, we also provide other products to meet your needs. With global certifications, ISO9001 quality standards, and export experience in over 20 countries serving 100+ industry clients, SunxFan offers not only products but customized engineering collaboration tailored to your precise system requirements.

Centrifugal Fans: Typically powered by AC motors, which may require external components like variable frequency drives (VFDs) for speed control. EC Fans: Utilize integrated brushless DC motors with built-in electronics for seamless speed control and reduced energy loss.

Yes. EC fans are typically quieter than AC fans due to smoother speed control and efficient brushless motor design.

The EC motor requires an indication of the desired fan speed. The desired fan speed is sent to the EC motor via a control signal. The control signal can be generated manually via a potentiometer or automatic via a sensor controller. Sensor controllers will adjust fan speed to keep the measured values within range.

EC fans are direct drive fans that are integrated into the cooling unit by replacing the centrifugal fans and motor assemblies. They are inherently more efficient than traditional centrifugal fans because of their unique design, which uses a brushless EC motor in a backward-curved motorized impeller.

Feel free to explore our comprehensive article on locomotive cooling fan and more info whenever you have a moment.

SF146A-E09,SF146D-E09,SF160A-E09,SF160D-E09 Double inlet centrifugal fan

From cotton picking to harvesting, SunxFan EC variable frequency Double Inlet Centrifugal fans

Centrifugal fan manufacturing expert in the field of marine blowers

Quick Links